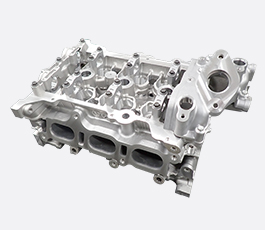

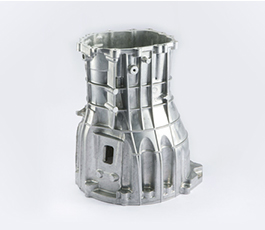

Cylinder blocks, in which iron casting liners have been installed through insert casting, are cast using High Pressure Die Casting (HPDC) method. With our continuous production approach from casting to machining utilizing flexible machining lines, we manufacture high-quality products at lower costs.